Rotary kiln is one kind of furnace which is widely used for calcined active lime production in the world.

Widely used in many industries such as construction materials, metallurgy, chemical and environmental protection.

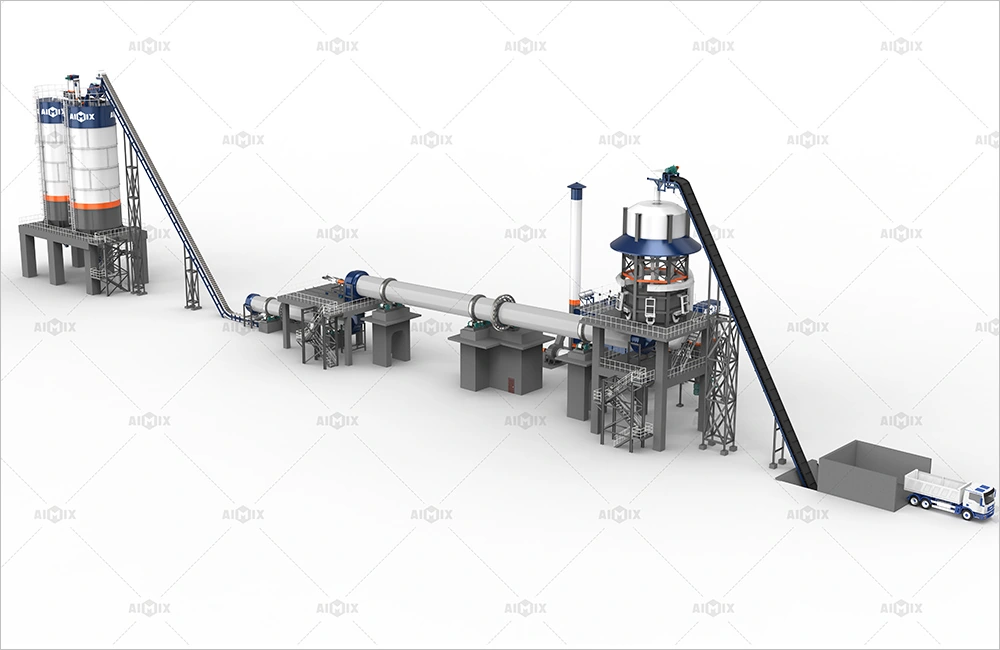

AIMIX is dedicated to the R&D of high-performance rotary kiln equipment, providing customized solutions such as cement kilns, lime kilns, ceramsite kilns, and metallurgical kilns. Designed to meet diverse process needs, our systems deliver stable performance, energy efficiency, and eco-friendly operation—trusted by clients across the building materials, metallurgy, and chemical sectors.

Cement Rotary Kiln

Deatil: The cement rotary kiln is primarily used for the calcination of cement clinker. AIMIX offers kilns in a range of specifications, with diameters from 3.0 meters to 6.0 meters and lengths from 48 meters to 62 meters, supporting daily production capacities from 700 to 3,000 tons.

Equipped with an advanced automated control system, our rotary kilns ensure precise temperature regulation and accurate material feeding, guaranteeing consistent clinker quality. In addition, each unit is fitted with a high-efficiency dust collection and exhaust gas treatment system, meeting environmental protection standards and minimizing emissions.

Applicable Raw Materials:

Limestone: The primary raw material for cement production; calcined to produce cement clinker.

Clay: Provides essential components such as silicon and aluminum for clinker formation.

Iron Ore: Used to adjust the chemical composition of clinker and enhance cement performance.

Lime Rotary Kiln

Deatil: The lime rotary kiln is a high-efficiency, energy-saving calcination equipment widely used for processing limestone, dolomite, magnesite, and other materials. AIMIX offers lime kilns with diameters ranging from 2.5 meters to 4.3 meters and lengths from 40 meters to 65 meters, supporting daily production capacities from 200 to 800 tons.

Our kilns are equipped with advanced automated control systems that ensure precise temperature regulation and accurate material feeding, resulting in stable and consistent product quality.

Applicable Materials:

Limestone: Calcined into quicklime, which is widely used in construction, metallurgy, and the chemical industry.

Dolomite: After calcination, used in the production of refractories, glass, and ceramics.

Magnesite: Calcined into raw materials for magnesia-based refractories and chemical applications.

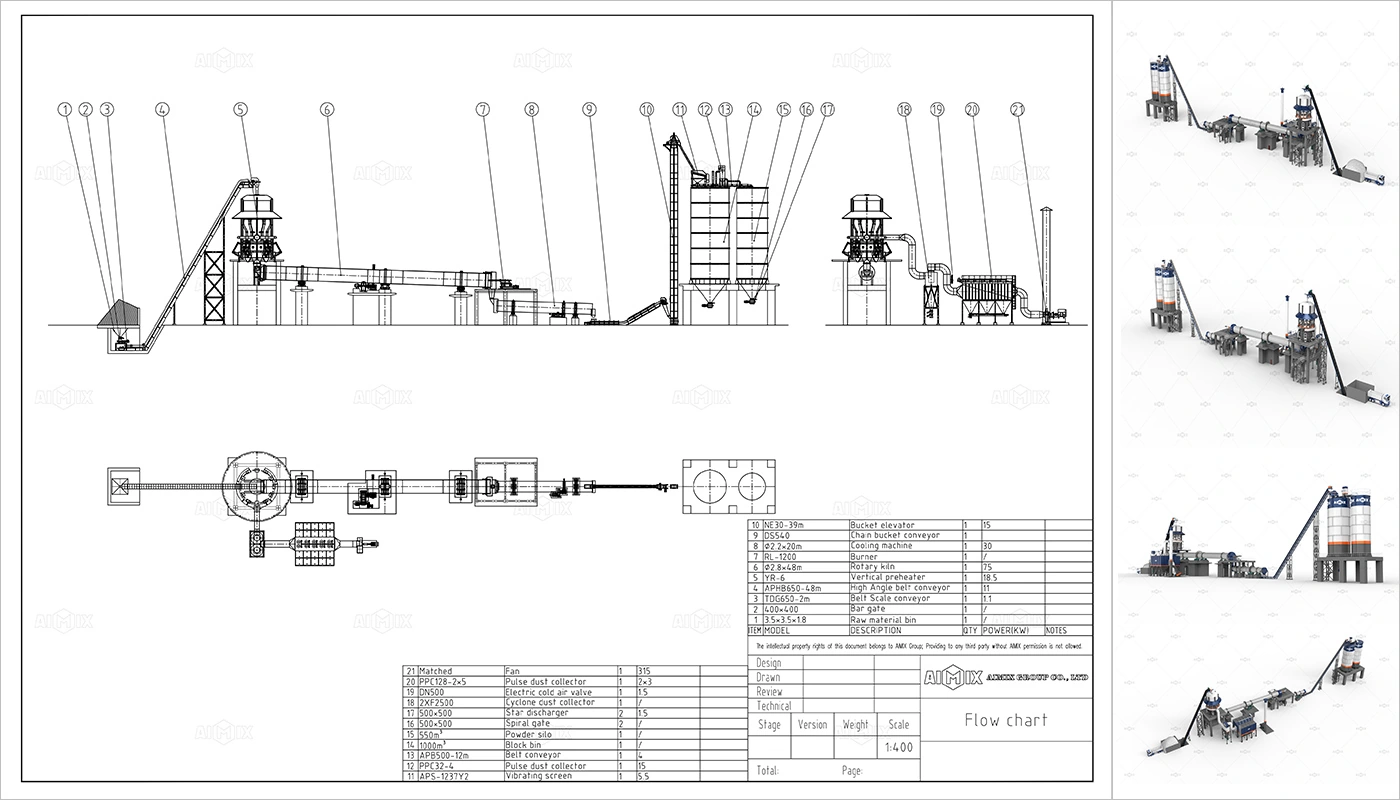

Process Flow Chart of 200 TPD Limestone Calcination Project

Layanan Lokal di Indonesia

AIMIX memiliki tim penjualan yang profesional, gudang luar negeri, kantor cabang di Indonesia, dan layanan yang lebih baik dan lebih cepat untuk pelanggan di Indonesia. Kami menyambut pelanggan di seluruh dunia untuk mengunjungi pabrik dan kantor kami di Cina dan Indonesia.

Desain Solusi Penghancuran

AIMIX dapat menyesuaikan pabrik penghancur untuk Anda berdasarkan kondisi spesifik proyek Anda: seperti lokasi konstruksi, kekerasan bahan mentah, keluaran, ukuran keluaran, anggaran, dll.

Instalasi & Pelatihan di Tempat

Tim kami menyediakan instalasi di lokasi dan pelatihan menyeluruh untuk memastikan pengoperasian pabrik penghancur yang aman.

Kontrol Kualitas & Pengiriman

Pemeriksaan kualitas yang ketat memastikan kepatuhan terhadap standar, dan kami menyediakan berbagai peralatan di beberapa lokasi untuk pengiriman cepat dan pelaksanaan proyek tepat waktu.

Dukungan Purna Jual

AIMIX menyediakan pasokan suku cadang, transformasi proyek, dan analisis pengembalian investasi. Tim dukungan 24/7 memberikan respons cepat dan pemeliharaan rutin.